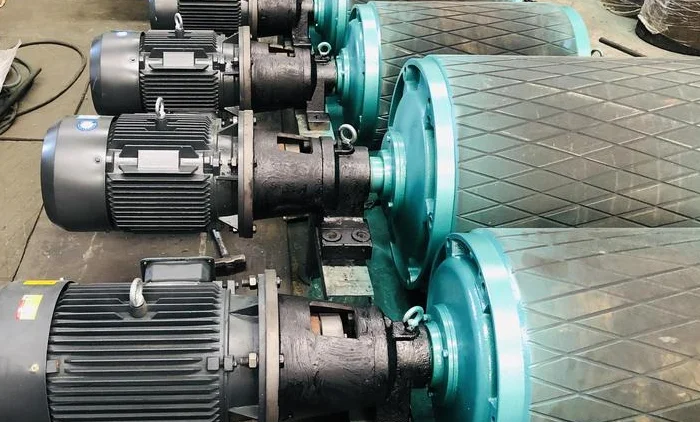

Reasons for motorized pulley burnout

Release time: 2022-01-10

1. When oil seepage occurs in the connection between motorized pulley end cover and pulley body, we should check whether the connecting bolts are loose, and check whether the venting screw plug and air outlet channel are blocked, and then carry out timely dredging and cleaning.

2. If the oil seepage phenomenon occurs in the oil plug of motorized pulley end cover, we need to tighten the oil plug and replace the oil-resistant rubber gasket frequently.

3. In the process of equipment use, if the motor current is low and the drum body stops not rotating, then we need to check whether the motor operation is normal, if the motor can operate normally, then it is likely to be the coupling pin fracture, in the replacement of the pin to restart the operation of the equipment to be supervised, this operation is to prevent the failure is not caused by the pin and then appear more serious consequences. This operation is to prevent more serious consequences if the fault is not caused by the pin.

4. If there is oil seepage at the junction box of motorized pulley, check whether the oil level is too high, then remove the junction box and tighten the oil sealing bolts.

5. If the equipment in the working process appears to be very noisy, it is necessary to check the coupling, frame rigidity, motor installation of the coaxiality of the specific method of operation is the drum from the bracket and then run the drum body alone. If the noise decreases, it means that you need to increase the rigidity of the bracket, after running for a period of time, the noise will be naturally reduced.

2024-08-29

Matters to be noted during the test run of drum motors

Check whether the wiring in the terminal box is correct and reliable.Check whether the amount of cooling lubricant reaches the height of 2/3 of the drum radius.

2024-08-29

What are the causes of motorized pulley shaft breakage?

Some applications in particular strictly adhere to the prescribed codes, not only to protect the motorized cylinder, but mainly to avoid the shaft output of the motorized cylinder being destroyed.

2024-08-29

What are the steps for assembling a motorized pulley?

First of all to rotate one of the pendulum wheel 180 degrees, that is to say, when the middle bearing hole and ten holes to reach the overlap

2022-07-28

Principles of motorized pulley selection

Generally speaking, motorized pulleys are designed according to standards, and their diameters are divided into Φ80. Φ113. Φ138. Φ165. Φ174 and Φ320.