What are the steps for assembling a motorized pulley?

Release time: 2024-08-29

1. First of all to rotate one of the pendulum wheel 180 degrees, that is to say, when the middle bearing hole and ten holes to reach the overlap, the outer gear type just misalignment, the top of the gear with the position just below the top of the tooth position. Note that the relative position of the two wheels must be remembered, it is recommended that they make a good mark, or they remember the position of the gear on the original labeling (here is a single tooth difference of the balance wheel, double tooth difference is not required to turn 180 degrees).

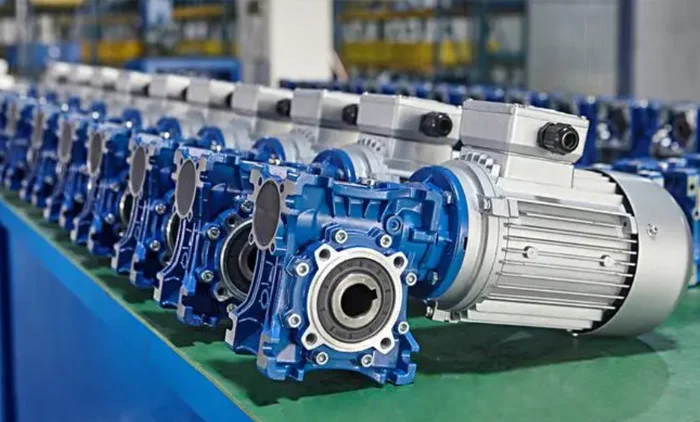

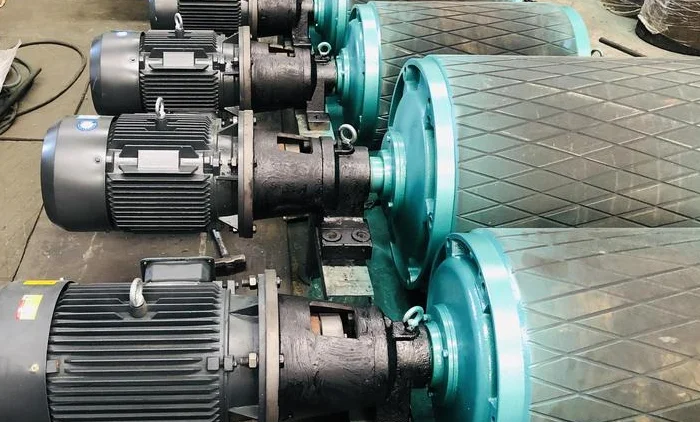

Motorized pulley

2. Then put a piece of cycloid into the needle gear shell, first hand rotation to see if it is smooth, is not rotating.

3. Next, put the eccentric bearing, because the bearing hole of the cycloid wheel is like a jacket of the eccentric bearing, so the exact position of the eccentric bearing should be the bearing hole of the following cycloid wheel, and the cylindrical balls of the eccentric bearing should be contained in all aspects.

4. Then into the spacer ring, is compared to the balance wheel smaller iron ring a, (now some have used not iron).

5. Next to enter the other side of the balance wheel, put this wheel is very critical, must be the balance wheel of the word above the steel seal and drum motor under the word of the balance wheel, are to face up, but also up and down the two balance wheel of the word of the steel seal is exactly divergent 180 degrees, and in a straight line, rather than up and down the two balance wheel of the word overlap placed, which is to pay special attention to this point.

6. The hole of the balance wheel corresponds to put on the sleeve, to use their own hands to rotate, to see if it can be rotated, check whether the installation is correct, such as if you can rotate smoothly, then you can install the seat part.

The motorized pulley after installation should be test run first to make sure there is no problem before it can be formally used, and it must be operated in accordance with the standard regulations, so as to avoid failure and damage caused by improper operation.

2024-08-29

Matters to be noted during the test run of drum motors

Check whether the wiring in the terminal box is correct and reliable.Check whether the amount of cooling lubricant reaches the height of 2/3 of the drum radius.

2024-08-29

What are the causes of motorized pulley shaft breakage?

Some applications in particular strictly adhere to the prescribed codes, not only to protect the motorized cylinder, but mainly to avoid the shaft output of the motorized cylinder being destroyed.

2024-08-29

What are the steps for assembling a motorized pulley?

First of all to rotate one of the pendulum wheel 180 degrees, that is to say, when the middle bearing hole and ten holes to reach the overlap

2022-07-28

Principles of motorized pulley selection

Generally speaking, motorized pulleys are designed according to standards, and their diameters are divided into Φ80. Φ113. Φ138. Φ165. Φ174 and Φ320.