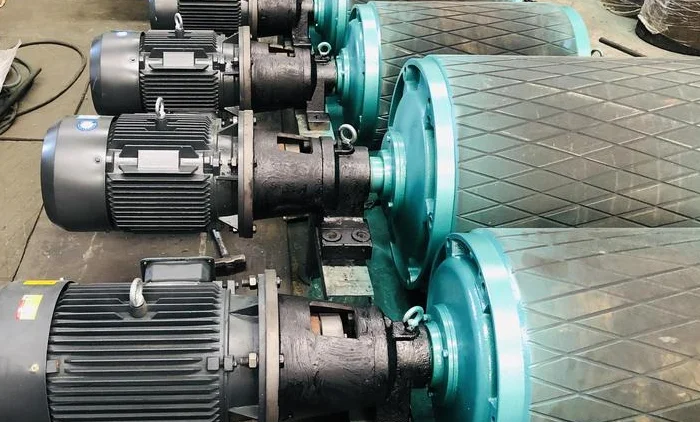

Principles of motorized pulley selection

Release time: 2022-07-28

With the rapid development of the drum motor industry and the continuous improvement of the level of technology, the scope of application of the equipment has become more and more extensive, but the same equipment is not in any case can be used at will, the next small make up will take you to look at the specific selection of equipment principles:

1. drum motor is generally installed horizontally, and the angle of its tilt can not exceed 5 °.

2. in other special conditions such as corrosion resistance, rubber, galvanized, etc. need to choose non-standard drum motor, and then after consultation with both parties by the manufacturer to help complete the design and manufacture.

3. Generally speaking, motorized pulleys are designed according to standards, and their diameters are divided into Φ80. Φ113. Φ138. Φ165. Φ174 and Φ320.

4、If the equipment is used in a very quiet environment, the corresponding ultra-quiet type should be used.

5. The width of motorized pulley is 270mm, but the cylinder diameter and length are different, so please consult the manufacturer for details.

Motorized pulley

6. according to customer demand can be customized drum motor, and its belt speed of 0.08m / s.

7. the equipment usually works in the temperature of +5 ℃ to +40 ℃, -20 ℃ to +5 ℃ (need to add low-temperature oil), the altitude does not exceed 1000m and the temperature of the conveyed material does not exceed 60 ℃ environment.

8. according to different roller conveyor and different applications can determine how much power with the drum motor appropriate.

2024-08-29

Matters to be noted during the test run of drum motors

Check whether the wiring in the terminal box is correct and reliable.Check whether the amount of cooling lubricant reaches the height of 2/3 of the drum radius.

2024-08-29

What are the causes of motorized pulley shaft breakage?

Some applications in particular strictly adhere to the prescribed codes, not only to protect the motorized cylinder, but mainly to avoid the shaft output of the motorized cylinder being destroyed.

2024-08-29

What are the steps for assembling a motorized pulley?

First of all to rotate one of the pendulum wheel 180 degrees, that is to say, when the middle bearing hole and ten holes to reach the overlap

2022-07-28

Principles of motorized pulley selection

Generally speaking, motorized pulleys are designed according to standards, and their diameters are divided into Φ80. Φ113. Φ138. Φ165. Φ174 and Φ320.