Matters to be noted during the test run of drum motors

Release time: 2024-08-29

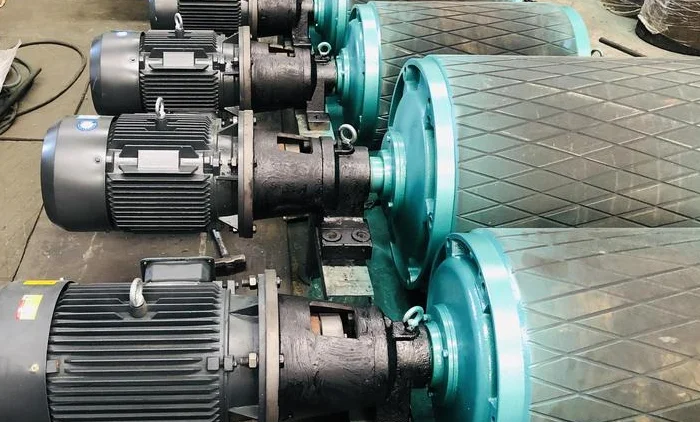

Matters to be noted in the test run of motorized pulley】Motorized pulley

1、Check whether the wiring in the terminal box is correct and reliable.

2、Check whether the amount of cooling lubricant reaches the height of 2/3 of the drum radius.

3、Check whether the motorized pulley's operation function is flexible by plucking the pulley by hand.

The following contents should be checked after the test run:

1. whether the operation is smooth, there is no periodic noise.

2. Whether there is any abnormal noise of the bearing.

3. There should be no loosening of the connecting bolts.

As the motorized pulley bearings are lubricated with grease to carry out lubrication work, so the motorized pulley needs a year to carry out a relatively large maintenance work, which brings big trouble to the user, so the motorized pulley is very important to pay attention to this point.

2024-08-29

Matters to be noted during the test run of drum motors

Check whether the wiring in the terminal box is correct and reliable.Check whether the amount of cooling lubricant reaches the height of 2/3 of the drum radius.

2024-08-29

What are the causes of motorized pulley shaft breakage?

Some applications in particular strictly adhere to the prescribed codes, not only to protect the motorized cylinder, but mainly to avoid the shaft output of the motorized cylinder being destroyed.

2024-08-29

What are the steps for assembling a motorized pulley?

First of all to rotate one of the pendulum wheel 180 degrees, that is to say, when the middle bearing hole and ten holes to reach the overlap

2022-07-28

Principles of motorized pulley selection

Generally speaking, motorized pulleys are designed according to standards, and their diameters are divided into Φ80. Φ113. Φ138. Φ165. Φ174 and Φ320.