What are the causes of motorized pulley shaft breakage?

Release time: 2024-08-29

First of all, the electric cylinder selection errors caused by the electric drum output, which is far from enough. Some users of the choice, wrongly feel that as long as the choice of the rated output torque of the electric cylinder, so that it can meet the work demand, in fact, not so, a mainly belongs to the value of the motor rated output torque reduction ratio, this issue in principle than the similar product samples provided by the rated output torque of the reducer, and secondly, you should also think about the drive motor's overload capacity and the torque of the actual work of the problem. Theoretically, the user needs a large torque. Need to be less than normal twice the rated output torque of the motorized cylinder.

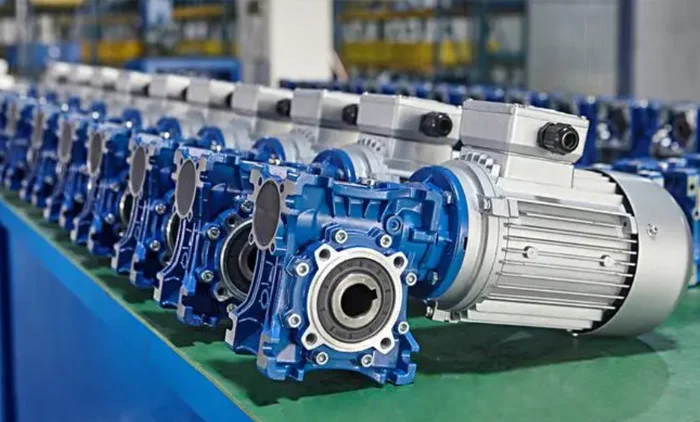

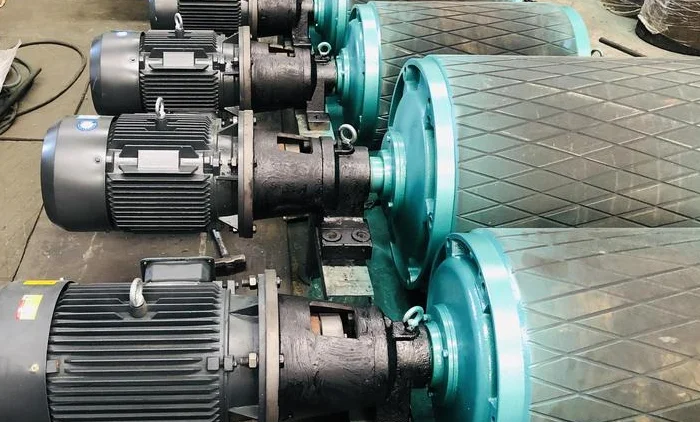

Drum Motors

Some applications in particular strictly adhere to the prescribed codes, not only to protect the motorized cylinder, but mainly to avoid the shaft output of the motorized cylinder being destroyed. The main reason for this is that if the mounting equipment in use, the motorized roller output shaft and the load are jammed, the overload capacity of the drive motor will continue to increase its output and, conversely, double the rated output and torque the output of the roller shaft may be generated.

Secondly, in the process of acceleration and deceleration, the instantaneous torque motorized pulley output shaft, if more than two times the rated output torque, then acceleration and deceleration at the same time relatively frequent, resulting in drum shaft breakage.

Drum motor in the use of the process to see, to pay more attention to the drum motor equipment output selection, if too high or too low will cause damage to the equipment, everyone in the daily operation of the use of, pay more attention to the requirements of this area, in order to avoid phenomena similar to the occurrence of such phenomena as broken shaft.

2024-08-29

Matters to be noted during the test run of drum motors

Check whether the wiring in the terminal box is correct and reliable.Check whether the amount of cooling lubricant reaches the height of 2/3 of the drum radius.

2024-08-29

What are the causes of motorized pulley shaft breakage?

Some applications in particular strictly adhere to the prescribed codes, not only to protect the motorized cylinder, but mainly to avoid the shaft output of the motorized cylinder being destroyed.

2024-08-29

What are the steps for assembling a motorized pulley?

First of all to rotate one of the pendulum wheel 180 degrees, that is to say, when the middle bearing hole and ten holes to reach the overlap

2022-07-28

Principles of motorized pulley selection

Generally speaking, motorized pulleys are designed according to standards, and their diameters are divided into Φ80. Φ113. Φ138. Φ165. Φ174 and Φ320.