Advantages of Drum Motor Conveyors

Release time: 2024-08-29

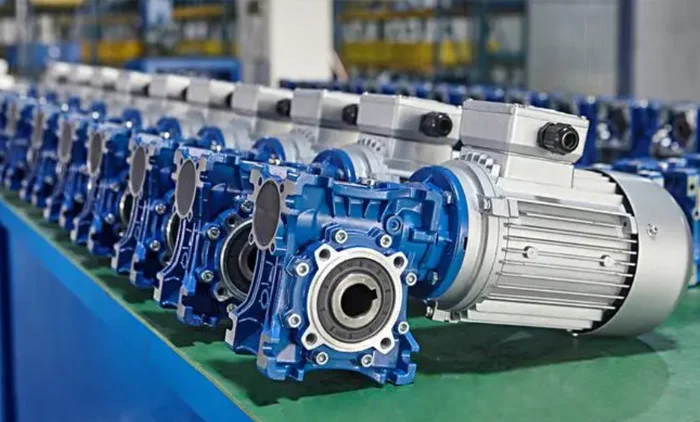

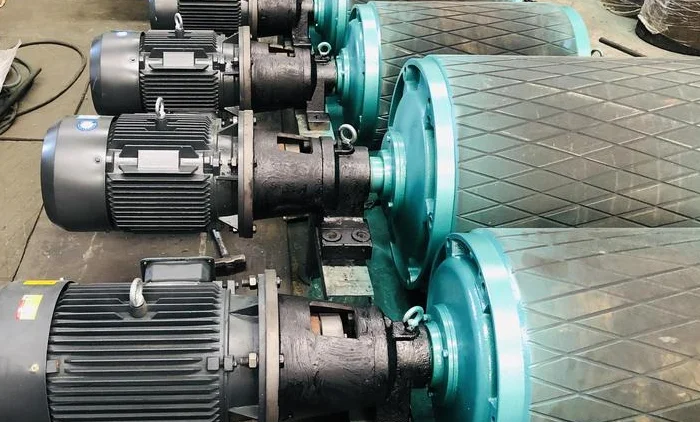

Motorized roller conveyor can use multiple roller conveyor and other conveying equipment or special machine to form a messy logistics conveyor system, in order to complete a variety of process requirements. Together with the choice of accumulating roller to complete the accumulation of material transportation. Motorized roller conveyor is mainly relying on the work of the motor to drive the roller to complete the transportation of materials. The motor plays the main role, and the production enterprises can select the motor according to the type and structure of the motor.

Motorized roller conveyor is used for all kinds of boxes, bags, rollers and other pieces of goods transportation with high reliability, simple structure, easy to use and maintain and other characteristics. Motorized roller conveyor is easy to connect between the filter, motorized roller conveyor according to the material can be divided into carbon steel roller conveyor, stainless steel roller conveyor. According to the conveyor form can be divided into linear roller conveyor, turning roller conveyor, screw roller conveyor, that the equipment has so many advantages, the next brief analysis with you how to choose the motor of the roller conveyor.

Motorized roller conveyor

Generally use three-phase communication power supply, therefore, if there is no special requirements should be selected communication motor. There are two types of communicating motors: asynchronous motors and same frequency motors. Asynchronous motor has cage type and wire-wound type two kinds, in which the general cage type asynchronous motor and synchronous motor two kinds.

Motorized drum conveyor electric work can be divided into two kinds of communicating motor and DC motor. Because the DC motor needs DC power supply, the structure is messy, the price is higher, the maintenance is more convenient, so no special bead requirements should not be selected.

2024-08-29

Matters to be noted during the test run of drum motors

Check whether the wiring in the terminal box is correct and reliable.Check whether the amount of cooling lubricant reaches the height of 2/3 of the drum radius.

2024-08-29

What are the causes of motorized pulley shaft breakage?

Some applications in particular strictly adhere to the prescribed codes, not only to protect the motorized cylinder, but mainly to avoid the shaft output of the motorized cylinder being destroyed.

2024-08-29

What are the steps for assembling a motorized pulley?

First of all to rotate one of the pendulum wheel 180 degrees, that is to say, when the middle bearing hole and ten holes to reach the overlap

2022-07-28

Principles of motorized pulley selection

Generally speaking, motorized pulleys are designed according to standards, and their diameters are divided into Φ80. Φ113. Φ138. Φ165. Φ174 and Φ320.