What are the drying methods for motorized pulleys?

Release time: 2024-08-29

1. Excitation coil drying method

The drum motor excitation coil drying method is to wind the excitation coil on the core of the drum stator coil, introduce alternating current to make the stator generate magnetic flux, and use its iron loss to dry the geared motor stator.

2. Fusion splicer drying method

Before the motorized pulley is operated, the terminals of the wet drum windings are connected in series and the chassis is grounded to heat and dry the three windings.

3. External heat source heating method

For damp motorized pulleys, first dismantle and check, then use high-power incandescent bulbs to bake in the equipment or dry in the drying room.

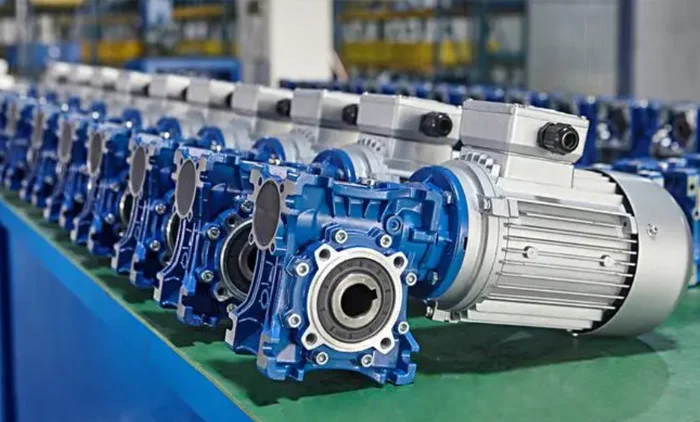

Motorized pulley domestic and foreign commonly used in the reducer device is fixed-axis gear transmission, more than 95 percent of the gear transmission is fixed-axis involute cylindrical gear transmission structure. This transmission has the advantages of simple structure, reliable performance, easy manufacturing, easy installation and maintenance, high efficiency and low noise.

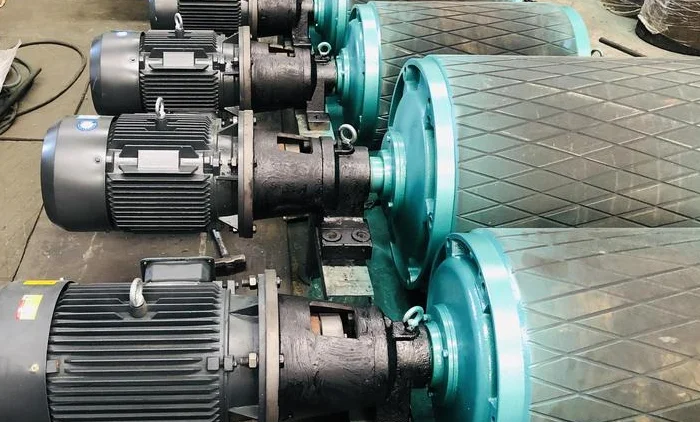

Motorized pulley can be used in any harsh conditions, it has relatively good load bearing capacity, and drying can extend its life. Hope the above is helpful to you.

2024-08-29

Matters to be noted during the test run of drum motors

Check whether the wiring in the terminal box is correct and reliable.Check whether the amount of cooling lubricant reaches the height of 2/3 of the drum radius.

2024-08-29

What are the causes of motorized pulley shaft breakage?

Some applications in particular strictly adhere to the prescribed codes, not only to protect the motorized cylinder, but mainly to avoid the shaft output of the motorized cylinder being destroyed.

2024-08-29

What are the steps for assembling a motorized pulley?

First of all to rotate one of the pendulum wheel 180 degrees, that is to say, when the middle bearing hole and ten holes to reach the overlap

2022-07-28

Principles of motorized pulley selection

Generally speaking, motorized pulleys are designed according to standards, and their diameters are divided into Φ80. Φ113. Φ138. Φ165. Φ174 and Φ320.