Internal structure of drum motors

Release time: 2021-11-12

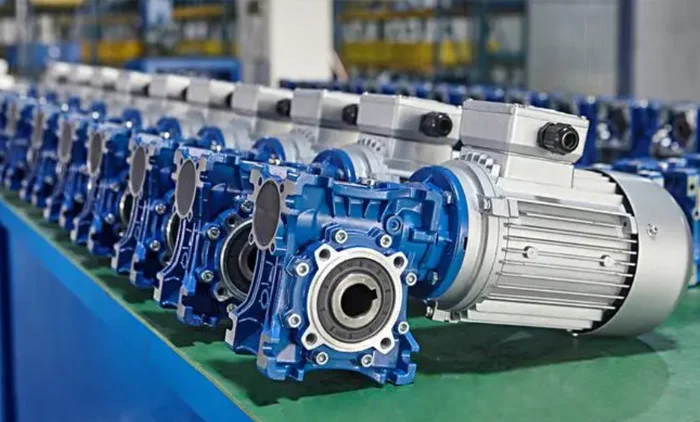

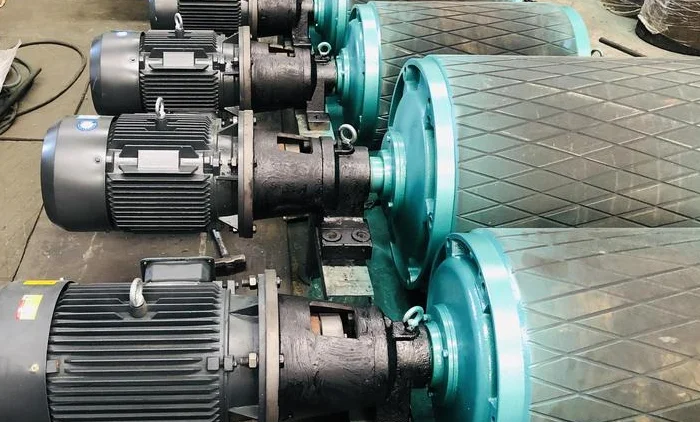

Friends familiar with the drum motor know that it is mainly the reducer and motor together inside the drum, belongs to a new type of drive equipment, the general situation is widely used in the conveyor. This equipment can have an advantage over other similar products, mainly by its internal structure, in order to allow users to better use the product, the following is the structure of the drum motor details:

In many of the reducer equipment, need to use some motorized selection of equipment. Because the drum is the idea of electricity and deceleration equipment as a collective in the drum body, and then the structure of the primary equipment is the idea of electricity and deceleration equipment of these two major parts. Motorized pulley includes some used to transfer the conveyor belt and promote its movement of the roller body, the use of the transfer of the roller itself, the successive shaft, support, including the roller body and the successive shaft connected to the motorized pulley gland, end caps, seals, bearings and other similar parts.

Certainly the structure of the drum motor exists in so many styles, but it is important zero equipment base is the same, in addition to the motor and transmission structure said earlier, but also very important, including the support of the drum motor, the right shaft, end cap, drum body, left shaft and other important parts. We all know that motorized pulley is applied to fixed and mobile belt conveyor, and because of this to replace the traditional electric motor, motorized pulley reducer is mainly in the drive outside of the separated drive equipment. We all know that the drum is the motor including the reduction equipment as a whole, placed inside the drum body, so the primary components of the drum structure is the motor and the reduction equipment of these two major parts. In addition to these uses, the drum motor has a roller body that is used to support the conveyor belt and drive it for movement, and the primary use of the drum motor is as a power source for the belt conveyor.

2024-08-29

Matters to be noted during the test run of drum motors

Check whether the wiring in the terminal box is correct and reliable.Check whether the amount of cooling lubricant reaches the height of 2/3 of the drum radius.

2024-08-29

What are the causes of motorized pulley shaft breakage?

Some applications in particular strictly adhere to the prescribed codes, not only to protect the motorized cylinder, but mainly to avoid the shaft output of the motorized cylinder being destroyed.

2024-08-29

What are the steps for assembling a motorized pulley?

First of all to rotate one of the pendulum wheel 180 degrees, that is to say, when the middle bearing hole and ten holes to reach the overlap

2022-07-28

Principles of motorized pulley selection

Generally speaking, motorized pulleys are designed according to standards, and their diameters are divided into Φ80. Φ113. Φ138. Φ165. Φ174 and Φ320.