Introduction to the structure of motorized pulleys

Release time: 2024-08-29

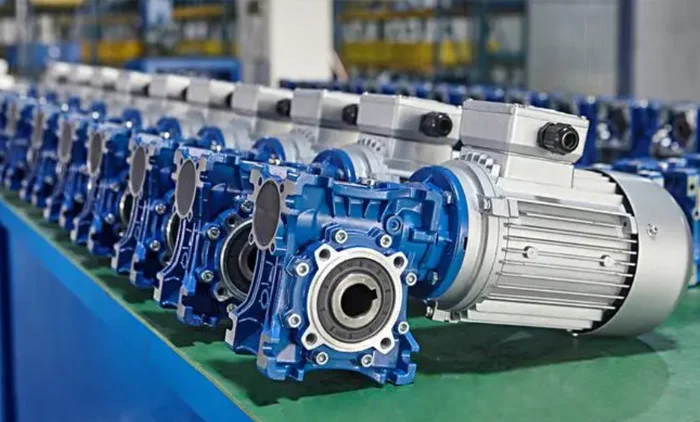

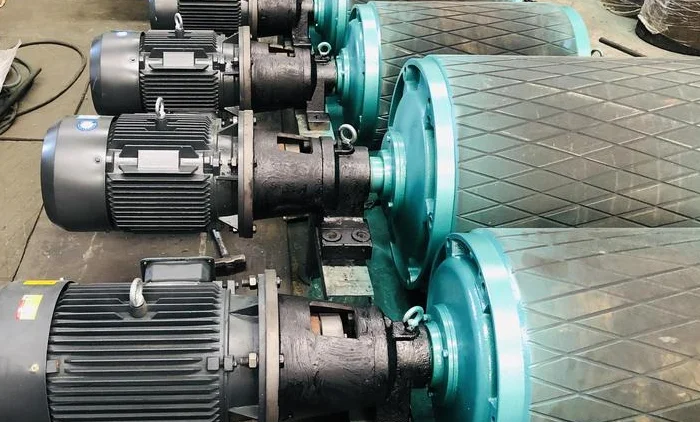

As the motorized pulley is placed in the drum body as a whole with the motor and reduction device, its main components are the motor and transmission mechanism of these two major parts, in order to deepen your understanding of the motorized pulley, to facilitate the later use of the motorized pulley, the motorized pulley manufacturer for us to introduce in detail its these two main institutions!

Electric motor: it is the power source of drum motor, and its working characteristics are as follows:

Long-time continuous work, so the electric motor is required for continuous work. The motor should have a large starting torque, and the starting current should not be too large.

Transmission mechanism: In order to meet the needs of different occasions, the transmission mechanism appears in a variety of forms, mainly:

1. involute gear parallel shaft fixed axis transmission mechanism;

2. involute planetary gear transmission;

3. differential wheel system institutions;

4. cycloid planetary transmission;

5. harmonic gear transmission;

6. variable speed bearing drive.

Although the structure of the drum motor in a variety of forms, but the main parts are basically the same, in addition to the previous brief description of the motor and transmission mechanism, there are mainly drum body, the right shaft, the left shaft, end cover, support and other major parts and bearings, seals, fasteners and other standard parts.

2024-08-29

Matters to be noted during the test run of drum motors

Check whether the wiring in the terminal box is correct and reliable.Check whether the amount of cooling lubricant reaches the height of 2/3 of the drum radius.

2024-08-29

What are the causes of motorized pulley shaft breakage?

Some applications in particular strictly adhere to the prescribed codes, not only to protect the motorized cylinder, but mainly to avoid the shaft output of the motorized cylinder being destroyed.

2024-08-29

What are the steps for assembling a motorized pulley?

First of all to rotate one of the pendulum wheel 180 degrees, that is to say, when the middle bearing hole and ten holes to reach the overlap

2022-07-28

Principles of motorized pulley selection

Generally speaking, motorized pulleys are designed according to standards, and their diameters are divided into Φ80. Φ113. Φ138. Φ165. Φ174 and Φ320.